Special Design for 272 Zirconia Oxide Sanding Belts - Types of sanding belts suitable for plates grinding and polishing – Fuke

Special Design for 272 Zirconia Oxide Sanding Belts - Types of sanding belts suitable for plates grinding and polishing – Fuke Detail:

Choosing the abrasive belt correctly and reasonably is not only to obtain a good grinding efficiency, but also to consider the service life of the abrasive belt. The main basis for selecting the abrasive belt is the grinding conditions, such as the characteristics of the grinding workpiece, the state of the grinding machine, the performance and technical requirements of the workpiece, and the production efficiency; on the other hand, it is also selected from the characteristics of the abrasive belt.

![]()

![]()

Silicon Carbide Series Products

Features:

Silicon carbide abrasives, blended fabric, dense planting sand, has the function of water and oil resistance. It can be used both dry and wet, and coolant can be added. It is suitable for various specifications of sanding belts.

Mainly used in:

All kinds of wood, plate, copper, steel, aluminum, glass, stone, circuit board, copper clad laminate, faucet, small hardware and various soft metals.

Abrasive grain: 60#-600#

Silicon carbide (SiC) is made from quartz sand, petroleum coke (or coal coke), and wood chips through high temperature smelting in a resistance furnace.

Including black silicon carbide and green silicon carbide:

Black silicon carbide is made of quartz sand, petroleum coke and high-quality silica as the main raw materials, and is smelted at high temperature in a resistance furnace. Its hardness is between corundum and diamond, its mechanical strength is higher than corundum, and it is brittle and sharp.

Green silicon carbide is made from petroleum coke and high-quality silica as the main raw materials, adding salt as an additive, and smelted at high temperature in a resistance furnace. Its hardness is between corundum and diamond, and its mechanical strength is higher than that of corundum.

Commonly used silicon carbide abrasives have two different crystals:

One is green silicon carbide, containing more than 97% SiC, which is mainly used for grinding hard gold-containing tools.

The other is black silicon carbide, which has a metallic luster and contains more than 95% SiC. It has greater strength than green silicon carbide but lower hardness. It is mainly used for grinding cast iron and non-metallic materials. The texture of black silicon carbide is brittle and harder than corundum abrasives, and its toughness is also inferior to corundum abrasives. For materials with lower tensile strength, such as non-metallic materials (various plates such as wood plywood, particleboard, high, medium and low density fiberboard , Bamboo board, calcium silicate board, leather, glass, ceramics, stone, etc.) and non-ferrous metals (aluminum, copper, lead, etc.) and other materials are particularly suitable for processing. It is also an ideal abrasive for processing hard and brittle materials.

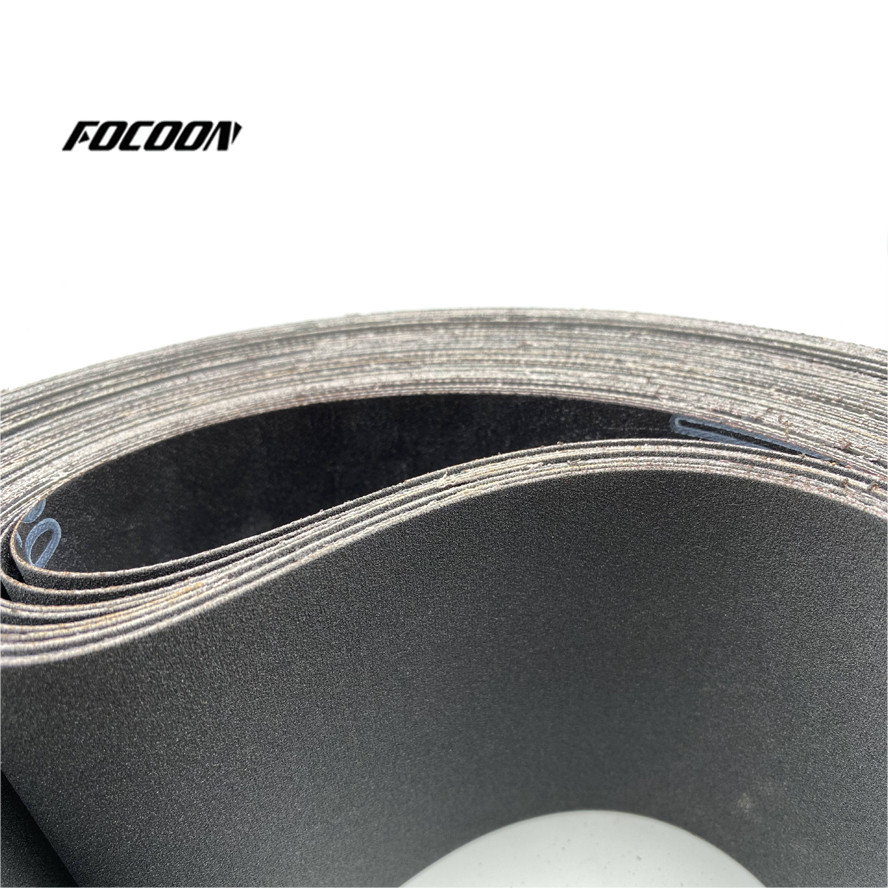

Product detail pictures:

Related Product Guide:

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for Special Design for 272 Zirconia Oxide Sanding Belts - Types of sanding belts suitable for plates grinding and polishing – Fuke , The product will supply to all over the world, such as: Mauritius, Czech republic, Rome, If any product meed your demand, remember to feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality merchandise, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.