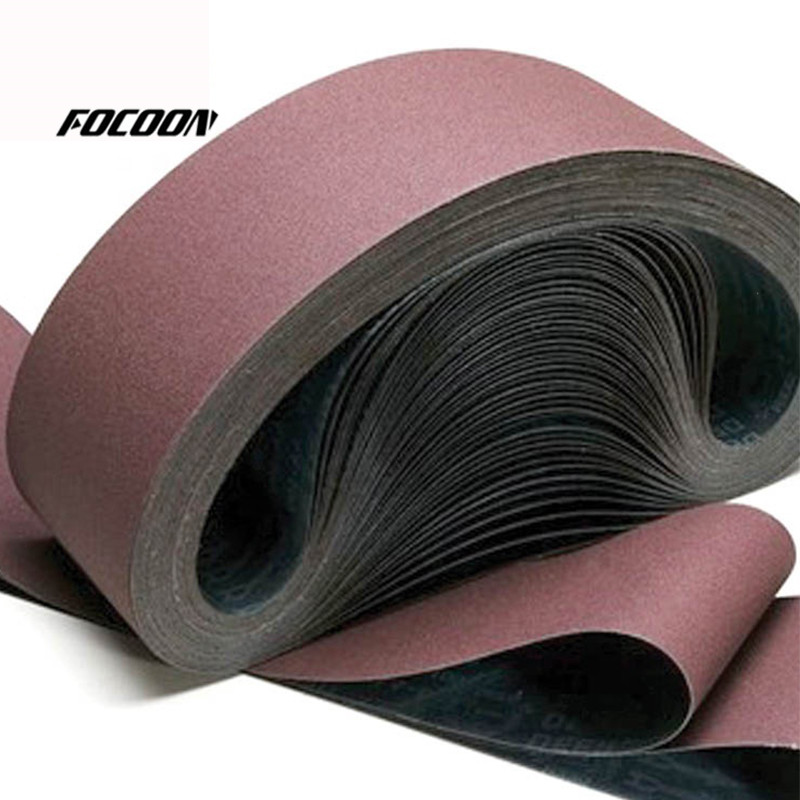

Brown fused alumina sanding belt Blended fabric cloth base Water and oil resistant

Be Applicable

It is widely used in metallurgy, machinery, shipbuilding, light industry, tanning, wood, building materials, textile printing and dyeing and other industries. Grinding and polishing of plywood, particle board, decorative board, bamboo and wood products and rattan products; Grinding and polishing of stainless steel, non-ferrous metals, ferrous metal plates and blades and other complex surfaces; Water or oil grinding of metal and non-metal materials, large surface grinding, polishing and napping of leather, rubber and plastics, and fabrics.

Operate

Automatic grinding, mechanical hand grinding, desktop grinding, manual tool grinding

Custom Made

Various specifications can be customized according to customer needs and non-standard

The abrasive belt has toughness and stiffness, suitable for narrow belt and medium width belt.

Advantage

Fast cutting, heat resistance, long service life, high efficiency and wear resistance.

Abrasive belt grinding can process workpieces of various shapes with high surface quality and precision requirements.

Polishing and grinding of large-area plates.

Continuous polishing and grinding of metal strips or wires.

Internal and external cylindrical polishing of workpieces with a large aspect ratio.

Polishing and grinding of complex and special-shaped workpieces.

Abrasive belt grinding equipment has various forms and varieties.

Product Display

The main chemical composition is AL2O3, which is made by smelting bauxite, iron filings and anthracite in an electric arc furnace at a high temperature above 2250℃. The color of Brown fused alumina abrasive is brown. This abrasive has certain hardness and toughness, strong grinding ability, and can withstand great pressure. It has the characteristics of high temperature resistance, oxidation resistance, corrosion resistance and good chemical stability. Due to its high tensile strength, it is suitable for grinding materials with high tensile strength, suitable for ordinary steel, high-carbon steel, alloy steel, and can be used for hard wood processing. It can also be used as a substitute when other abrasives are insufficient. It is called an abrasive and is a widely used abrasive.

The abrasive grain size of the abrasive belt has a great influence on the grinding productivity and the surface roughness of the processing. In order to ensure the roughness and processing efficiency of the workpiece, it should be based on the different requirements of the processing, the performance of the machine tool, and the specific conditions of the processing, such as the processing allowance of the workpiece, The surface condition, material, heat treatment, precision, roughness are different to choose different grit belts. Generally speaking, coarse grit is used for coarse grinding and fine grit is used for fine grinding. (The following data is for reference only, and the actual processing conditions are related to the performance of the machine tool and processing parameters, etc.)

| Abrasive grain size | Processing accuracy range |

| P16-P24 | Rough grinding of castings and weldments, de-pouring risers, flashing, etc. |

| P30-P40 | Rough grinding of inner and outer circles, flat surfaces and curved surfaces Ra6.3~3.2 |

| P50-P120 | Semi-precision grinding, fine grinding of inner and outer circles, flat surfaces and curved surfaces Ra3.2~0.8 |

| P150-P240 | Fine grinding, forming grinding Ra0.8~0.2 |

| P250-P1200 | Precision grinding Ra≦0.2 |

| P1500-3000 | Ultra-precision grinding Ra≦0.05 |

| P6000-P20000 | Ultra-precision machining Ra≦0.01 |