OEM Supply 3×18 Sanding Belts - Types of sanding belts suitable for plates grinding and polishing – Fuke

OEM Supply 3×18 Sanding Belts - Types of sanding belts suitable for plates grinding and polishing – Fuke Detail:

Choosing the abrasive belt correctly and reasonably is not only to obtain a good grinding efficiency, but also to consider the service life of the abrasive belt. The main basis for selecting the abrasive belt is the grinding conditions, such as the characteristics of the grinding workpiece, the state of the grinding machine, the performance and technical requirements of the workpiece, and the production efficiency; on the other hand, it is also selected from the characteristics of the abrasive belt.

![]()

![]()

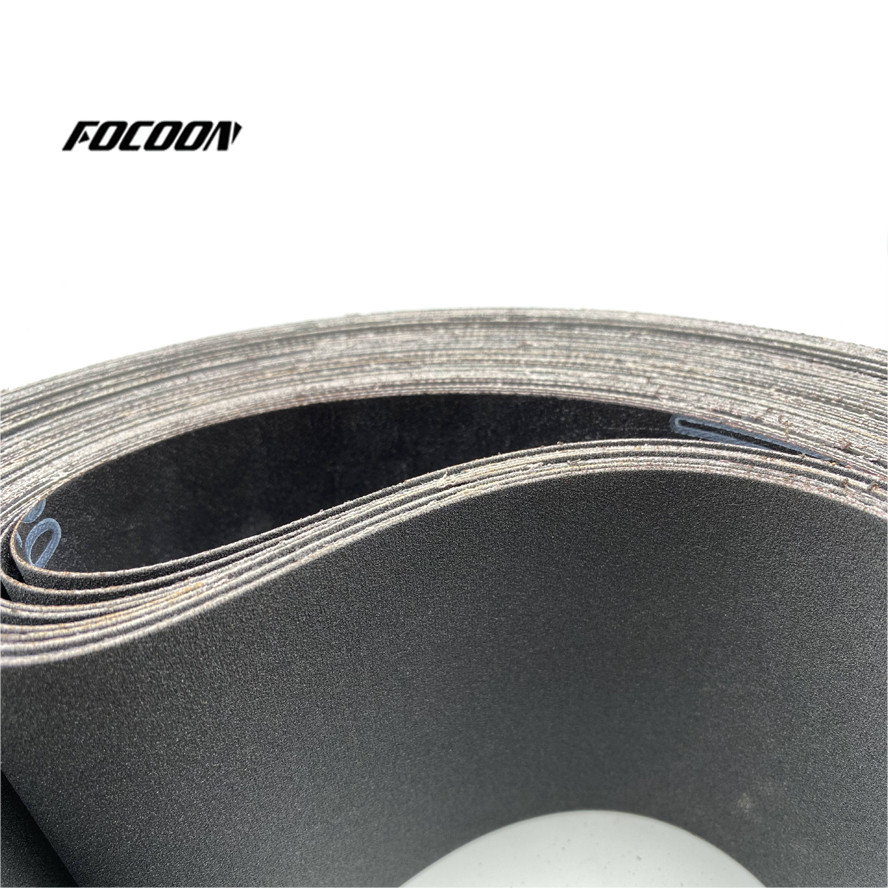

Silicon Carbide Series Products

Features:

Silicon carbide abrasives, blended fabric, dense planting sand, has the function of water and oil resistance. It can be used both dry and wet, and coolant can be added. It is suitable for various specifications of sanding belts.

Mainly used in:

All kinds of wood, plate, copper, steel, aluminum, glass, stone, circuit board, copper clad laminate, faucet, small hardware and various soft metals.

Abrasive grain: 60#-600#

Silicon carbide (SiC) is made from quartz sand, petroleum coke (or coal coke), and wood chips through high temperature smelting in a resistance furnace.

Including black silicon carbide and green silicon carbide:

Black silicon carbide is made of quartz sand, petroleum coke and high-quality silica as the main raw materials, and is smelted at high temperature in a resistance furnace. Its hardness is between corundum and diamond, its mechanical strength is higher than corundum, and it is brittle and sharp.

Green silicon carbide is made from petroleum coke and high-quality silica as the main raw materials, adding salt as an additive, and smelted at high temperature in a resistance furnace. Its hardness is between corundum and diamond, and its mechanical strength is higher than that of corundum.

Commonly used silicon carbide abrasives have two different crystals:

One is green silicon carbide, containing more than 97% SiC, which is mainly used for grinding hard gold-containing tools.

The other is black silicon carbide, which has a metallic luster and contains more than 95% SiC. It has greater strength than green silicon carbide but lower hardness. It is mainly used for grinding cast iron and non-metallic materials. The texture of black silicon carbide is brittle and harder than corundum abrasives, and its toughness is also inferior to corundum abrasives. For materials with lower tensile strength, such as non-metallic materials (various plates such as wood plywood, particleboard, high, medium and low density fiberboard , Bamboo board, calcium silicate board, leather, glass, ceramics, stone, etc.) and non-ferrous metals (aluminum, copper, lead, etc.) and other materials are particularly suitable for processing. It is also an ideal abrasive for processing hard and brittle materials.

Product detail pictures:

Related Product Guide:

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we're the lowest around for OEM Supply 3×18 Sanding Belts - Types of sanding belts suitable for plates grinding and polishing – Fuke , The product will supply to all over the world, such as: Montreal, Lahore, Malaysia, Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.