Low MOQ for Sanding Belt Manufacturers - Types of sanding belt suitable for stone polishing and grinding – Fuke

Low MOQ for Sanding Belt Manufacturers - Types of sanding belt suitable for stone polishing and grinding – Fuke Detail:

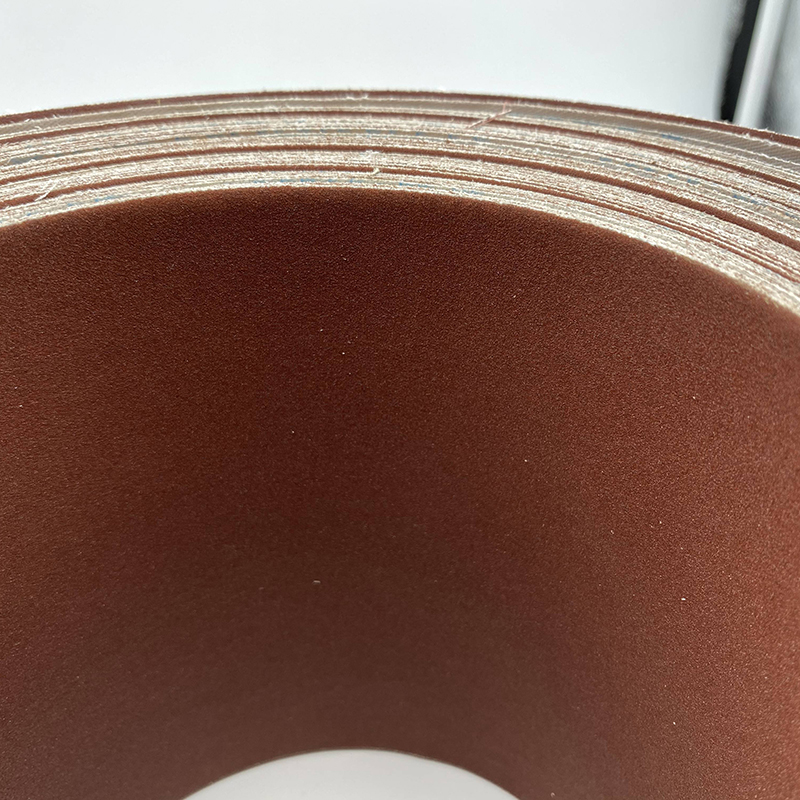

Brown fused alumina Series Products

Brown fused alumina is an artificial corundum produced by melting and reducing three raw materials: bauxite, carbon material and iron filings in an electric arc furnace. The main chemical component is AL2O3, the content of which is 95.00%-97.00%, and a small amount of Fe, Si, Ti, etc.

![]()

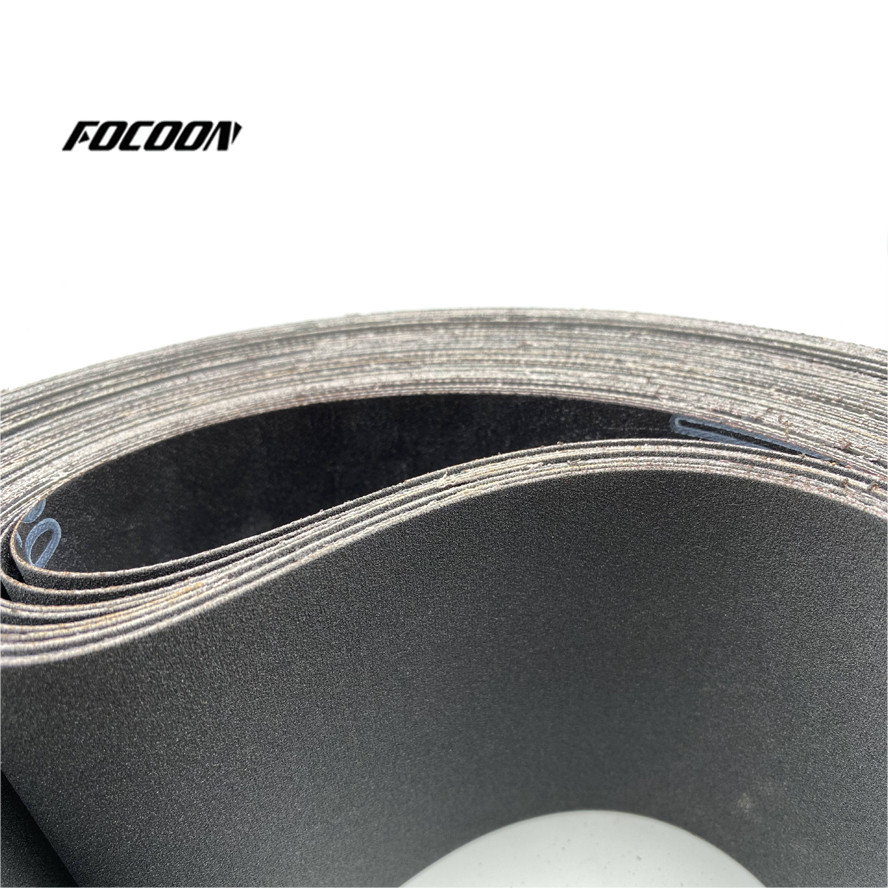

Silicon Carbide Series Products

Silicon carbide is an inorganic substance with a chemical formula of SiC. It is made by high temperature smelting of raw materials such as quartz sand, petroleum coke (or coal coke), and wood chips (salt is needed to produce green silicon carbide) through a resistance furnace. There are two basic varieties of silicon carbide, black silicon carbide and green silicon carbide, both of which belong to α-SiC.

The characteristics of different stones

1. Marble is made on the basis of limestone. Its surface has good decorative properties after being ground and polished. However, its material is very soft and easily affected by external interference.

2. The surface layer of granite is hard and belongs to volcanic rock, and it has excellent wear resistance and corrosion resistance. It is usually used on kitchen countertops or on the ground.

3. Inorganic artificial stone has no carbon atoms inside, so its hardness is better than that of organic artificial stone.

4. The density of organic artificial stone is high, it will not absorb water easily, and it has good sealing performance, and the exfoliation rate is better than that of inorganic artificial stone. However, the texture is similar to plastic and will be affected by thermal expansion and contraction.

The base material of the abrasive belt must have a certain strength and a small elongation.

The strength of the base material is closely related to the strength of the abrasive belt. Only with high strength, the abrasive belt can withstand the impact of tensile load, alternating load, grinding load and expansion load during the grinding process.

Elongation is also a very important indicator of the base material. If the abrasive belt extends greatly under the action of external force, the abrasive particles will fall off and lose the grinding ability. Excessive extension will exceed the adjustable range of the abrasive belt tension of the grinder. As a result, the abrasive belt cannot be used.

Polishing Method

1. Contact wheel type

The abrasive belt grinds by contacting the workpiece with the contact wheel. It can be used to process the outer circle, inner hole and plane of the workpiece, and the contact wheel can be made into a certain shape to form the curved surface of the workpiece. Grinding with floating contact wheels can also be used for accompanying processing of irregular profiles.

2. Grinding plate type

During grinding, the abrasive belt contacts the workpiece through the pressure grinding plate. The pressure-grinding plate has a pressing effect and is generally used for plane processing, which can increase the contact area, improve the grinding efficiency and the geometric accuracy of the workpiece, especially the flatness.

3. Freestyle

The workpiece is in direct contact with the flexible abrasive belt without any object supporting the abrasive belt. It uses its own flexibility after the belt is tensioned to grind or polish the workpiece. This method is easy to adapt to the contour of the workpiece within a certain range, especially the irregular shape of the workpiece, and is mostly used in the processing of outer molding surface and chamfering, deburring, polishing and other processes.

Product detail pictures:

Related Product Guide:

Our target is always to satisfy our customers by offering golden support, superior value and high quality for Low MOQ for Sanding Belt Manufacturers - Types of sanding belt suitable for stone polishing and grinding – Fuke , The product will supply to all over the world, such as: Mongolia, Romania, Accra, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.