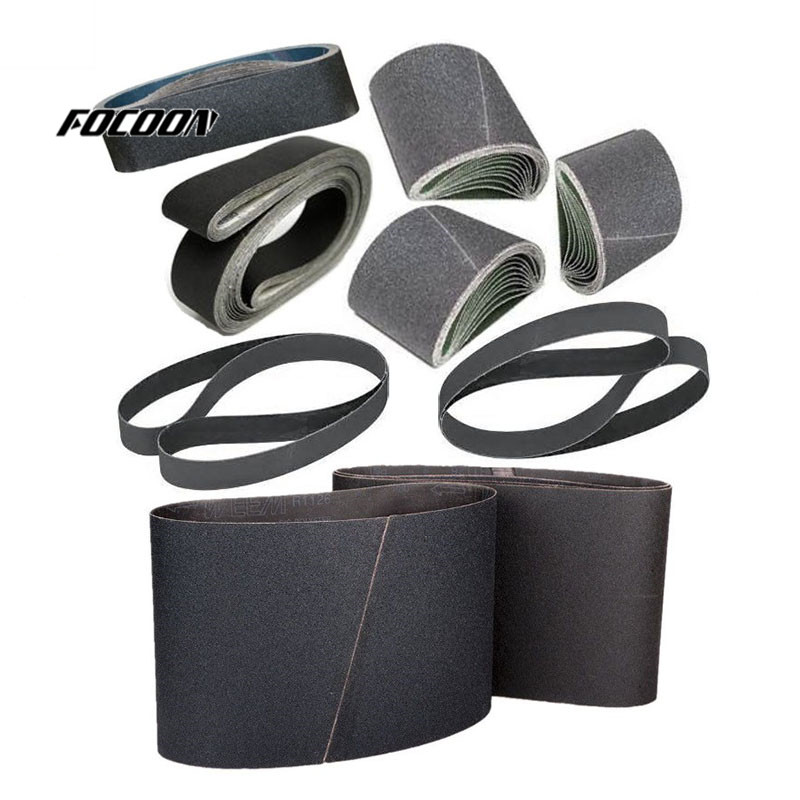

Factory Free sample Warrior Sanding Belts - Silicon carbide sanding belt Cloth or Paper backing Wet and Dry – Fuke

Factory Free sample Warrior Sanding Belts - Silicon carbide sanding belt Cloth or Paper backing Wet and Dry – Fuke Detail:

Be applicable

It is widely used in the grinding and polishing of various wooden plates, steel, copper, aluminum, alloys, glass, non-ferrous metals, ceramics, porcelain, minerals, stone, rubber, and synthetic materials. It has the function of heat resistance and waterproof, suitable for dry grinding, and can be added with coolant. The sand surface is sharp, with very high strength and grinding ability, suitable for the grinding of medium and high density plates, and can also be used for fine processing of metal surfaces, which can achieve good results. For the rough, medium and finish processing of the product surface, it can achieve excellent grinding results. The fabric base has strong tension and ultra-wide sub-tension, which can be used for ultra-large abrasive belts.

operate:

Automatic grinding, mechanical hand grinding, desktop grinding, manual tool grinding

custom made:

Various specifications can be customized according to customer needs and non-standard

Silicon carbide (SiC) is made from quartz sand, petroleum coke (or coal coke), and wood chips through high temperature smelting in a resistance furnace.

Including black silicon carbide and green silicon carbide:

Black silicon carbide is made of quartz sand, petroleum coke and high-quality silica as the main raw materials, and is smelted at high temperature in a resistance furnace. Its hardness is between corundum and diamond, its mechanical strength is higher than corundum, and it is brittle and sharp.

Green silicon carbide is made from petroleum coke and high-quality silica as the main raw materials, adding salt as an additive, and smelted at high temperature in a resistance furnace. Its hardness is between corundum and diamond, and its mechanical strength is higher than that of corundum.

Commonly used silicon carbide abrasives have two different crystals:

One is green silicon carbide, containing more than 97% SiC, which is mainly used for grinding hard gold-containing tools.

The other is black silicon carbide, which has a metallic luster and contains more than 95% SiC. It has greater strength than green silicon carbide but lower hardness. It is mainly used for grinding cast iron and non-metallic materials. The texture of black silicon carbide is brittle and harder than corundum abrasives, and its toughness is also inferior to corundum abrasives. For materials with lower tensile strength, such as non-metallic materials (various plates such as wood plywood, particleboard, high, medium and low density fiberboard , Bamboo board, calcium silicate board, leather, glass, ceramics, stone, etc.) and non-ferrous metals (aluminum, copper, lead, etc.) and other materials are particularly suitable for processing. It is also an ideal abrasive for processing hard and brittle materials.

The abrasive grain size of the abrasive belt has a great influence on the grinding productivity and the surface roughness of the processing. In order to ensure the roughness and processing efficiency of the workpiece, it should be based on the different requirements of the processing, the performance of the machine tool, and the specific conditions of the processing, such as the processing allowance of the workpiece, The surface condition, material, heat treatment, precision, roughness are different to choose different grit belts. Generally speaking, coarse grit is used for coarse grinding and fine grit is used for fine grinding. (The following data is for reference only, and the actual processing conditions are related to the performance of the machine tool and processing parameters, etc.)

| Abrasive grain size | Processing accuracy range |

| P16-P24 | Rough grinding of castings and weldments, de-pouring risers, flashing, etc. |

| P30-P40 | Rough grinding of inner and outer circles, flat surfaces and curved surfaces Ra6.3~3.2 |

| P50-P120 | Semi-precision grinding, fine grinding of inner and outer circles, flat surfaces and curved surfaces Ra3.2~0.8 |

| P150-P240 | Fine grinding, forming grinding Ra0.8~0.2 |

| P250-P1200 | Precision grinding Ra≦0.2 |

| P1500-3000 | Ultra-precision grinding Ra≦0.05 |

| P6000-P20000 | Ultra-precision machining Ra≦0.01 |

Product detail pictures:

Related Product Guide:

We love an incredibly fantastic standing amid our consumers for our superb item high quality, aggressive rate and also the finest assistance for Factory Free sample Warrior Sanding Belts - Silicon carbide sanding belt Cloth or Paper backing Wet and Dry – Fuke , The product will supply to all over the world, such as: Uzbekistan, Miami, Colombia, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.