1. The basic structural elements of the sanding belt:

Sanding belts are generally composed of three basic elements: Base material, Binder and abrasives.

Base material: Cloth base, Paper base, Composite base.

Binder: Animal glue, Semi-resin, Full resin, Water-resistant products.

Abrasives: Brown corundum, silicon carbide, zirconium corundum, ceramics, calcined, artificial diamond.

Joint method: Flat joint, Lap joint, Butt joint.

2. The use range of sanding belt:

(1). Panel processing industry: raw wood, plywood, fiberboard, particle board, veneer, furniture, building materials and others;

(2). Metal processing industry: non-ferrous metals, ferrous metals,;

(3). Ceramics, leather, fiber, paint, plastic and rubber products, stone and other industries.

3. Selection of sanding belt:

Choosing the sanding belt correctly and reasonably is not only to obtain good grinding efficiency, but also to consider the service life of the sanding belt. The main basis for selecting the sanding belt is the grinding conditions, such as the characteristics of the grinding workpiece, the state of the grinding machine, the performance and technical requirements of the workpiece, and the production efficiency. On the other hand, it must be selected from the characteristics of the sanding belt.

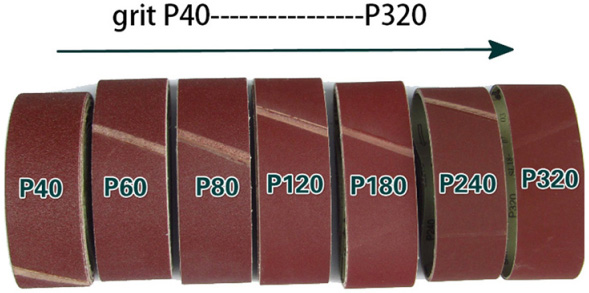

(1). Grain size selection:

Generally speaking, the choice of abrasive grain size is to consider the grinding efficiency and the surface finish of the workpiece. For different workpiece materials, the grain size ranges of sanding belts for rough grinding, intermediate grinding and fine grinding are shown in the following table.

| Workpiece material | Rough grinding | Middle grinding | Fine grinding | Grinding method |

| Steel | 24-60 | 80-120 | 150-W40 | Dry and wet |

| Non-ferrous metals | 24-60 | 80-150 | 180-W50 | Dry and wet |

| Wood | 36-80 | 100-150 | 180-240 | Dry |

| Glass | 60-120 | 100-150 | 180-W40 | Wet |

| Paint | 80-150 | 180-240 | 280-W20 | Dry and wet |

| Leather | 46-60 | 80-150 | 180-W28 | Dry |

| Rubber | 16-46 | 60-120 | 150-W40 | Dry |

| Plastic | 36-80 | 100-150 | 180-W40 | Wet |

| Ceramics | 36-80 | 100-150 | 180-W40 | Wet |

| Stone | 36-80 | 100-150 | 180-W40 | Wet |

(2) . Binder selection:

According to different binder, sanding belts can be divided into four types: animal glue sanding belts (commonly known as dry sanding belts), semi-resin sanding belts, full resin sanding belts and water-resistant sanding belts. The range of application is as follows:

① Animal glue belts are cheap and easy to manufacture, and are mainly suitable for low-speed grinding.

② The semi-resin sanding belt improves the disadvantages of poor moisture resistance and heat resistance of the animal glue sanding belt, greatly improving the bonding performance, and the grinding performance is doubled when the price increases little. It is widely used in metal and non-metal grinding, especially in the wood and leather processing industry more popular.

③ The all-resin sanding belt is made of high-quality synthetic resin\high-strength cotton cloth and high-quality abrasives. The cost is relatively high, but it is wear-resistant and can be strongly ground. It is up to the task when high-speed operation, large cutting, and high-precision grinding are required. The above three kinds of sanding belts are suitable for dry grinding, and can also be ground in oil, but they are not water resistant.

④ Compared with the above-mentioned sanding belts, water-resistant sanding belts have higher requirements for raw materials and more complicated manufacturing processes, resulting in less output and higher prices. It has the characteristics of resin sanding belt, and it can also be directly used for water coolant grinding.

(3). Base material selection:

Paper base

Single-layer lightweight paper 65-100g/m2 is light, thin, soft, low tensile strength, and low cost. It is mostly used for fine grinding or medium grinding, suitable for manual or vibratory sanding machine. Polishing of complex-shaped workpieces, sanding of curved woodware, polishing of metal and wood finishes, and grinding of precision instruments and meters, etc.

Multi-layer medium-sized paper 110-130g/m2 is thicker, flexible, and has higher tensile strength than light-weight paper. Used for manual or hand-held polishing machines to manufacture sheet-shaped and roll-shaped sandpaper. Derusting and polishing of metal workpieces, sanding of wood furniture, polishing of primer putty, machine polishing of lacquer, polishing of watch cases and instruments, etc.

Multi-layer heavy-duty paper 160-230g/m2 is thick, flexible, high tensile strength, low elongation, and high toughness. Used for manufacturing paper sanding belts for machining. It is suitable for drum sander, wide belt sander and general belt grinder, mainly processing plywood, particleboard, fiberboard, leather and woodware.

Cloth base

Lightweight cloth (twill), very soft, light and thin, moderate tensile strength. For manual or low-load machine use. Metal parts grinding and rust removal, polishing, drum sanding machine plate processing, sewing machine frame processing, light-duty sanding belts.

Medium-sized cloth (coarse twill), good flexibility, thick and high tensile strength. General machine sanding belts, and heavy-duty sanding belts, such as furniture, tools, electric irons, sand steel sheets, and engine blade type grinding.

Heavy-duty cloth (satin) is thick and has a higher strength in the weft direction than in the warp direction. It is suitable for heavy-duty grinding. Used for processing large-area plates.

Composite base

Particularly thick, high strength, anti-wrinkle, anti-tensile and anti-breakage. Heavy-duty sanding belt, especially suitable for the processing of guillotine board, fiberboard, plywood and the grinding processing of inlaid flooring, etc. The steel paper is extremely thick, with high strength, low elongation and good heat resistance. Mainly used for sand disc, welding seam, rust removal, metal skin and oxide layer removal, etc.

4.Selection of abrasives:

Usually it is the workpiece material with higher tensile strength. Choose corundum abrasive with greater toughness, higher pressure resistance, strong resistance to crushing, high temperature resistance and chemical stability;

For metal and non-metal workpieces with low tensile strength and high toughness, choose silicon carbide abrasives with high hardness, high brittleness, and fragility, such as: glass, brass, leather, rubber, ceramics, jade, particleboard, fiberboard, etc.

5.Treatment before use of sanding belt:

When using the sanding belt, the running direction should be consistent with the direction marked on the back of the sanding belt, so as to prevent the sanding belt from breaking during operation or affecting the surface quality of the processing plant's workpieces. The sanding belt should be rotated for a few minutes before grinding, and the grinding should be started when the sanding belt is running normally.

The sanding belt should be suspended before use, that is, the unpacked sanding belt should be hung on a 100-250mm diameter pipe and let it hang for 2 to 3 days. The choice of pipe diameter should be determined according to the grain sizes of the sanding belt. When hanging, the joint should be at the upper end of the pipe and the pipe should be horizontal.

Post time: Jun-03-2019