Abrasive belt grinding is a soft grinding method, which is a compound processing technology with multiple functions of grinding and polishing.

The abrasive grains on the abrasive belt have a stronger cutting ability than the abrasive grains of the grinding wheel, so its grinding efficiency is very high, which is reflected in its removal rate, grinding ratio (the ratio of the weight of the removed workpiece to the weight of the abrasive wear) and the power of the machine The utilization rate is high in all three aspects.

Abrasive belt grinding makes the surface of the workpiece high in quality. Because it has multiple functions of grinding and polishing, and compared with grinding wheel grinding, belt grinding is called "cold grinding", that is, the grinding temperature is low, and the surface of the workpiece is not easy to burn.

The high surface quality of the workpiece is manifested in the small surface roughness value, good residual stress state, and no microscopic cracks or metallographic structure changes on the surface. The residual stress on the surface of abrasive belt grinding workpiece is mostly in the state of compressive stress, and its value is generally -60~-5Kg/mm², while the grinding wheel grinding is mostly tensile stress, so the abrasive belt grinding is very helpful to strengthen the surface of the workpiece, improve the fatigue strength of the workpiece.

The abrasive belt grinding system has low vibration and good stability. Due to the light weight of the abrasive belt, the balance of the grinding process structure system is easy to control. All the rotating parts (such as contact wheels, driving wheels, tension wheels, etc.) wear very little, and there will be no dynamic imbalance like the grinding wheel. factor. In addition, the elastic grinding effect of the abrasive belt can greatly reduce or absorb the vibration and impact generated during grinding. The grinding speed is stable, and the belt drive wheel will not be like a grinding wheel. The smaller the diameter, the slower the speed will be.

The abrasive belt has high grinding precision. Due to the improvement of abrasive belt production quality and the production level of abrasive belt grinders, abrasive belt grinding has already entered the ranks of precision and ultra-precision machining, with the highest accuracy reaching below 0.1mm.

Low cost of abrasive belt grinding:

The equipment is simple. Compared with the grinding wheel grinder, the belt grinder is much simpler. This is mainly because the belt is light in weight, the grinding force is small, the vibration during the grinding process is small, and the rigidity and strength requirements of the machine tool are much lower than the grinding wheel grinder.

The operation is simple and the auxiliary time is less. Whether it is manual or motorized belt grinding, its operation is very easy. From changing and adjusting the abrasive belt to clamping the workpiece to be processed, all of this can be completed in a short time.

The grinding ratio is large, the power utilization rate of the machine tool is high, and the cutting efficiency is high. This reduces the cost of tools and energy for cutting materials of the same weight or volume, and takes a short time.

Abrasive belt grinding is very safe, with low noise and dust, easy to control, and good environmental benefits.

Because the sanding belt itself is very light, there is no danger of injury even if it breaks. Abrasive belt grinding is not as serious as the sand out of the grinding wheel, especially during dry grinding, the grinding debris is mainly the material of the workpiece to be processed, and it is easy to recover and control dust. Due to the rubber contact wheel, the abrasive belt grinding will not form a rigid impact on the workpiece like a grinding wheel, so the processing noise is very small, usually <70dB. It can be seen that from the perspective of environmental protection, belt grinding is also very worthy of promotion.

Abrasive belt grinding process is flexible and adaptable:

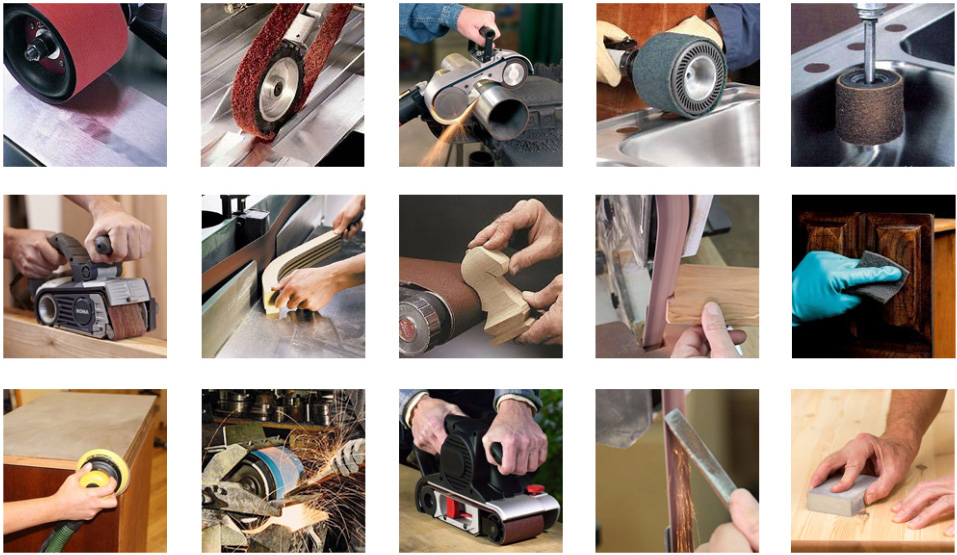

Abrasive belt grinding can be conveniently used for the grinding of flat surfaces, inner and outer circles and complex curved surfaces. Designing an abrasive belt grinding head device as a functional part can be installed on a lathe for post-turning grinding, and can also be installed on a planer for use, and it can also be designed as a variety of special grinding machines. Using this feature of belt grinding can easily solve some difficult-to-machine parts, such as the precision machining of super long and super large shafts and plane parts.

The superior grinding performance and flexible process characteristics of abrasive belt determine that it has an extremely wide range of applications, from daily life to industrial production in all walks of life, abrasive belt grinding almost covers all fields. The variety of application forms and the wide range are unmatched by any other processing method. Specifically, it can grind almost all engineering materials. In addition to materials that can be processed by grinding wheels, abrasive belts can also process non-ferrous metals such as copper and aluminum, and non-metallic soft materials such as wood, leather, and plastic. In particular, the "cold" grinding effect of belt grinding makes it more unique when processing heat-resistant and difficult-to-grind materials.

Post time: Jan-13-2022